Experimental Sounding Rocket

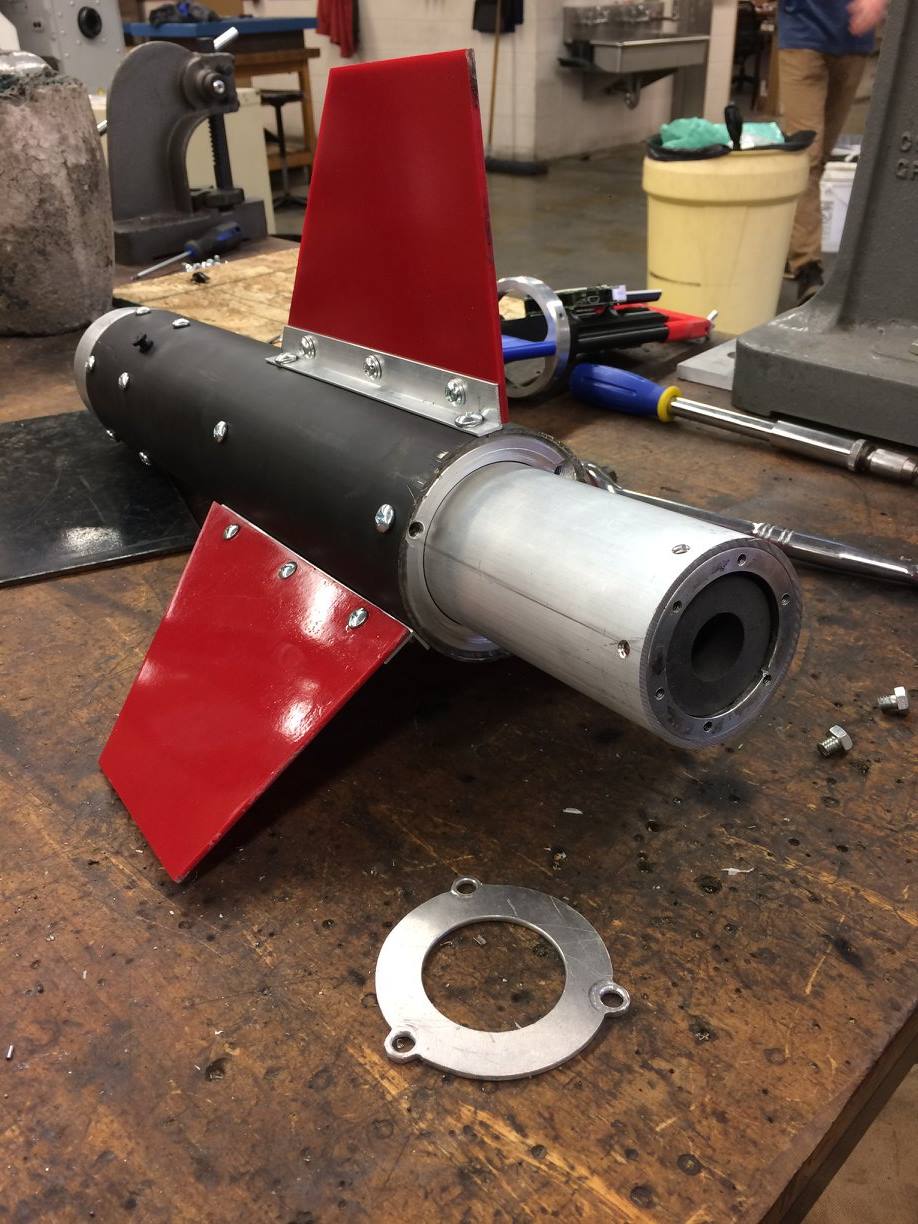

Fully in-house made, 8-ft-tall solid propellant rocket designed for competing in the Intercollegiate Rocket Engineering Competition (IREC) in 2015, 2016, and 2017, elevating to 10,000 ft.

The rocket features avionics, payload, propulsion, and recovery systems designed and entirely manufactured in-house by BYU-Idaho's Rocket Dynamics student organization—from the graphite nozzle and solid propellant, to the parachute.

Solid-fuel Propulsion

Tailoring and mixing of Ammonium Perchlorate Composite Propellant (APCP) to achieve a mission of 10,000 ft, along with the design and manufacture of the motor (graphite nozzle and aluminium pressure vessel).

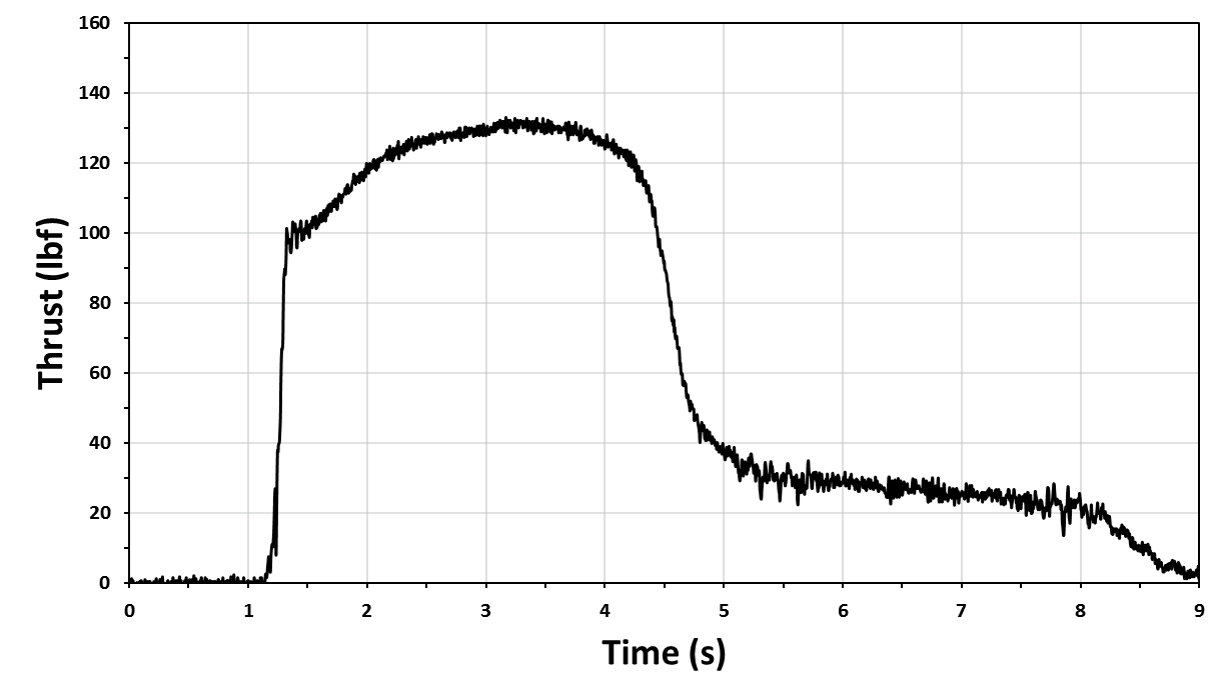

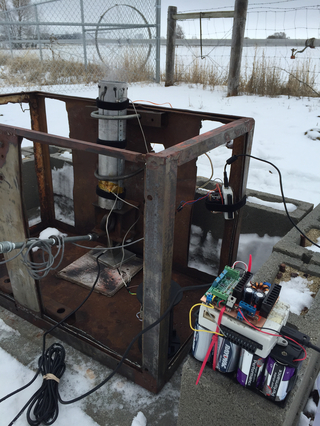

Managed all testing procedures and data adquisition (DAQ), testing the fuel and motor's perfomance in static-fire through thrust measurements from a load cell, and combustion dynamics from pressure transducers and thermocouples.

Designed a remote-controlled DAQ system for the measurement of pressure in the combustion chamber during flight.

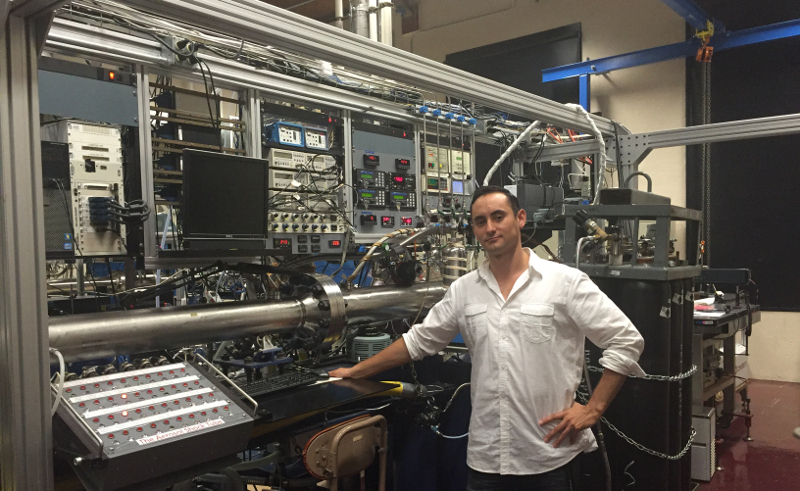

Combustion of Liquid Fuel

Recipient of the Stanford Undergraduate Research Fellowship to work at the High Temperature Gasdynamics lab under Prof. Ronald K. Hanson. Research on shock tube experimentation of chemical kinetics of jet and rocket fuels, attaining practical experience in principles of combustion and laser diagnostics. Helped develop a one-dimensional gasdynamics (compressible CFD + chemical kinetics) FORTRAN code as a tool for design of shock tube experiments.